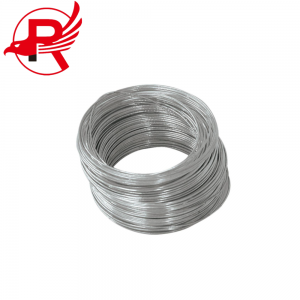

Günstiger, hochwertiger BWG 20 21 22 SAE1008 GI verzinkter Bindedraht

| Produktname | |

| 5 kg/Rolle, PP-Folie innen und hassianisches Gewebe außen oder PP-Gewebesack außen | |

| 25 kg/Rolle, PP-Folie innen und hassianisches Gewebe außen oder PP-Gewebesack außen | |

| 50 kg/Rolle, PP-Folie innen und hassianisches Gewebe außen oder PP-Gewebesack außen | |

| Material | Q195/Q235 |

| Produktionsmenge | 1000 Tonnen/Monat |

| Mindestbestellmenge | 5 Tonnen |

| Anwendung | Bindedraht |

| Zahlungsbedingungen | T/T |

| Lieferzeit | etwa 3-15 Tage nach Vorauszahlung |

| Drahtstärke | SWG (mm) | BWG(mm) | Metrisch (mm) |

| 8 | 4.05 | 4.19 | 4 |

| 9 | 3,66 | 3,76 | 4 |

| 10 | 3,25 | 3.4 | 3,5 |

| 11 | 2,95 | 3.05 | 3 |

| 12 | 2,64 | 2,77 | 2.8 |

| 13 | 2.34 | 2.41 | 2,5 |

| 14 | 2.03 | 2.11 | 2,5 |

| 15 | 1,83 | 1,83 | 1.8 |

| 16 | 1,63 | 1,65 | 1,65 |

| 17 | 1,42 | 1,47 | 1.4 |

| 18 | 1.22 | 1,25 | 1.2 |

| 19 | 1.02 | 1.07 | 1 |

| 20 | 0,91 | 0,84 | 0,9 |

| 21 | 0,81 | 0,81 | 0,8 |

| 22 | 0,71 | 0,71 | 0,7 |

| Drahtnummer (Drahtstärke) | AWG oder B&S (Zoll) | AWG Metrisch (MM) | Drahtnummer (Drahtstärke) | AWG oder B&S (Zoll) | AWG Metrisch (MM) |

| 1 | 0,289297" | 7,348 mm | 29 | 0,0113" | 0,287 mm |

| 2 | 0,257627" | 6,543 mm | 30 | 0,01" | 0,254 mm |

| 3 | 0,229423" | 5,827 mm | 31 | 0,0089" | 0,2261 mm |

| 4 | 0,2043" | 5,189 mm | 32 | 0,008" | 0,2032 mm |

| 5 | 0,1819" | 4,621 mm | 33 | 0,0071" | 0,1803 mm |

| 6 | 0,162" | 4,115 mm | 34 | 0,0063" | 0,1601 mm |

| 7 | 0,1443" | 3,665 mm | 35 | 0,0056" | 0,1422 mm |

| 8 | 0,1285" | 3,264 mm | 36 | 0,005" | 0,127 mm |

| 9 | 0,1144" | 2,906 mm | 37 | 0,0045" | 0,1143 mm |

| 10 | 0,1019" | 2,588 mm | 38 | 0,004" | 0,1016 mm |

| 11 | 0,0907" | 2,304 mm | 39 | 0,0035" | 0,0889 mm |

| 12 | 0,0808" | 2,052 mm | 40 | 0,0031" | 0,0787 mm |

| 13 | 0,072" | 1,829 mm | 41 | 0,0028" | 0,0711 mm |

| 14 | 0,0641" | 1,628 mm | 42 | 0,0025" | 0,0635 mm |

| 15 | 0,0571" | 1,45 mm | 43 | 0,0022" | 0,0559 mm |

| 16 | 0,0508" | 1,291 mm | 44 | 0,002" | 0,0508 mm |

| 17 | 0,0453" | 1,15 mm | 45 | 0,0018" | 0,0457 mm |

| 18 | 0,0403" | 1,024 mm | 46 | 0,0016" | 0,0406 mm |

| 19 | 0,0359" | 0,9119 mm | 47 | 0,0014" | 0,035 mm |

| 20 | 0,032" | 0,8128 mm | 48 | 0,0012" | 0,0305 mm |

| 21 | 0,0285" | 0,7239 mm | 49 | 0,0011" | 0,0279 mm |

| 22 | 0,0253" | 0,6426 mm | 50 | 0,001" | 0,0254 mm |

| 23 | 0,0226" | 0,574 mm | 51 | 0,00088" | 0,0224 mm |

| 24 | 0,0201" | 0,5106 mm | 52 | 0,00078" | 0,0198 mm |

| 25 | 0,0179" | 0,4547 mm | 53 | 0,0007" | 0,0178 mm |

| 26 | 0,0159" | 0,4038 mm | 54 | 0,00062" | 0,0158 mm |

| 27 | 0,0142" | 0,3606 mm | 55 | 0,00055" | 0,014 mm |

| 28 | 0,0126" | 0,32 mm | 56 | 0,00049" | 0,0124 mm |

1)kaltgewalzter, verzinkter Stahldrahtwird in großem Umfang im Bauwesen, im Kunsthandwerk, bei der Herstellung von Drahtgeflecht, bei der Produktion von verzinktem Hakengeflecht, Lehmgeflecht, Leitplanken, bei Produktverpackungen sowie im täglichen Gebrauch und in anderen Bereichen eingesetzt.

Im KommunikationssystemWalzdraht aus verzinktem Kohlenstoffstahlist geeignet für Übertragungsleitungen wie Telegrafie, Telefonie, Kabelrundfunk und Signalübertragung.

Im Energiesystem kann der Stahldraht aufgrund seiner relativ großen und dicken Zinkschicht mit guter Korrosionsbeständigkeit zur Armierung von Kabeln mit starker Leitungskorrosion eingesetzt werden.

2) ROYAL GROUPVerzinkter Stahldraht, der sich durch höchste Qualität und starke Lieferfähigkeit auszeichnet, findet breite Anwendung im Stahlbau und im Konstruktionswesen.

1. Kostenlose Muster, 100%ige Qualitätsgarantie nach dem Kauf, Unterstützung aller Zahlungsmethoden;

2. Alle anderen Spezifikationen vonPPGIsind je nach Ihren Anforderungen verfügbar

Anforderung (OEM & ODM)! Den Fabrikpreis erhalten Sie von der ROYAL GROUP.

Bei der Herstellung von verzinktem Stahldraht wird zunächst der Rohstoff Kohlenstoffstahldraht verwendet. Die Verarbeitung erfolgt durch Blechbearbeitung, Beizen, Waschen, Verseifen, Trocknen, Ziehen, Glühen, Abkühlen, Beizen, Waschen, Verzinken, Verpacken und weitere Verfahren.

Die Herstellung von verzinktem Stahldraht umfasst mehrere Schritte, um ein langlebiges und korrosionsbeständiges Produkt zu erzeugen. Hier ein Überblick über den typischen Produktionsprozess:

- DrahtzeichnungDer Prozess beginnt mit dem Ziehen von Stahldraht durch eine Reihe von Ziehdüsen, um seinen Durchmesser auf die gewünschte Größe zu reduzieren. Dieser Schritt trägt auch zur Verbesserung der Zugfestigkeit und der Oberflächenbeschaffenheit des Drahtes bei.

- GlühenDer gezogene Draht wird anschließend einem Glühprozess unterzogen, bei dem er auf eine bestimmte Temperatur erhitzt und dann langsam abgekühlt wird. Dadurch werden innere Spannungen abgebaut und der Draht für die Weiterverarbeitung weicher gemacht.

- EinlegenDer Draht wird in einer Säurelösung gebeizt, um Zunder, Rost oder andere Verunreinigungen von der Oberfläche zu entfernen und so eine gute Haftung der Verzinkung zu gewährleisten.

- VerzinkenDer gebeizte Draht wird anschließend in ein Bad aus geschmolzenem Zink getaucht, entweder durch Feuerverzinken oder durch elektrolytisches Verzinken. Beim Feuerverzinken wird der Draht vollständig in ein Bad aus geschmolzenem Zink eingetaucht, während beim elektrolytischen Verzinken eine dünne Zinkschicht auf die Drahtoberfläche abgeschieden wird.

- Abkühlen und AbschreckenNach dem Verzinken wird der Draht abgekühlt und abgeschreckt, um die Zinkschicht zu verfestigen und ihre Haftung auf dem Stahldraht zu verbessern.

- Nach der BehandlungJe nach den spezifischen Anforderungen können dem verzinkten Stahldraht zusätzliche Verfahren wie Passivierung, Chromatierung oder das Aufbringen eines Schmiermittels unterzogen werden, um seine Leistung und sein Aussehen zu verbessern.

- Spulen und VerpackenDer fertige verzinkte Stahldraht wird anschließend gemäß den Kundenspezifikationen aufgespult und für Versand und Vertrieb verpackt.

Während des gesamten Produktionsprozesses werden Qualitätskontrollmaßnahmen durchgeführt, um sicherzustellen, dass der verzinkte Stahldraht die Industriestandards hinsichtlich Zugfestigkeit, Schichtdicke und Korrosionsbeständigkeit erfüllt. Darüber hinaus spielen Umwelt- und Sicherheitsaspekte beim Umgang mit und der Entsorgung der beim Beizen und Verzinken verwendeten Chemikalien eine wichtige Rolle.

Die Verpackung erfolgt in der Regel durch wasserdichte Verpackung, Stahldrahtbindung, sehr robust.

Transport: Expressversand (Musterlieferung), Luftfracht, Schienentransport, Landtransport, Seefracht (FCL, LCL oder Massengut)

F: Sind Sie Hersteller?

A: Ja, wir sind ein Hersteller. Wir haben eine eigene Fabrik in Tianjin, China.

F: Kann ich eine Probebestellung von nur wenigen Tonnen aufgeben?

A: Selbstverständlich. Wir können die Fracht für Sie per LCL-Service (Teilladung) versenden.

F: Ist die Probe kostenlos?

A: Das Muster ist kostenlos, aber der Käufer trägt die Versandkosten.

F: Sind Sie ein Gold-Lieferant und bieten Sie Handelssicherung an?

A: Wir sind seit sieben Jahren Goldlieferant und akzeptieren Handelsgarantien.